QSenS is a highly advanced AI-powered video analytics platform that uses real-time computer vision, data analytics, and sensor networks. Designed for warehousing and logistics companies, It enables data-driven decisions for futuristic, more advanced business management.

SENSE BEYOND SIGHT!

Expand your business and reach new customers by launching your online store today. Showcase your goods and services to a global audience, increase sales, and provide a seamless shopping experience, all from the comfort of the digital world.

Accurately record every truck arrival and departure time for every cycle.

Monitor initial and interim idle times to track delays from truck arrival to work cycles.

Auto detection of loading or unloading activity and monitoring the entire cycle duration.

Counting the number of cardboard boxes being moved over each palette.

Real-time tracking of number of persons deployed each cycle and avg. man hours

Robust analytics engine that transforms raw data into actionable insights.

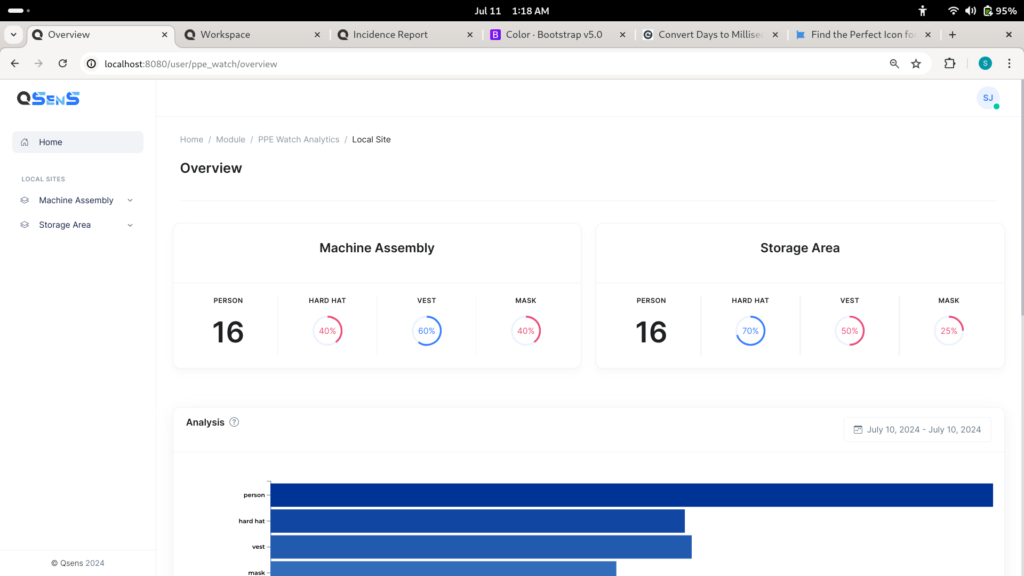

Personal Protective Equipment monitoring is crucial in reducing workplace incidents, while adherence is challenging.

Computer vision–powered PPE monitoring ensures workers stay protected, driving real-time safety and accountability on every site.

Real-time reporting of Safety gear usage at all critical touch points ensure minimal incidents.

With the use of Artificial intelligence techniques, the system automatically tracks and sends alerts of non-compliance reduce reliance on human reporting.

The system enables you to mark certain areas of the workplace as hazardous or dangerous for worker activity, thus triggering alerts when an intrusion is detected.

Optimizing forklift utilization is crucial for businesses that rely on material handling operations

Investing in forklift tracking technology is a strategic move for businesses aiming to enhance warehouse efficiency, safety, and long-term profitability.

Real-time tracking of forklifts via AR markers.

Velocity monitoring to assess forklift movement patterns.

Active runtime vs. stationary time analysis to optimize utilization.

Incident reporting system to log near-miss collisions.

Individual forklift performance tracking.

Active runtime vs. stationary time analysis to optimize utilization.

lead to better decision-making.

enhances productivity and safety.

cuts costs and improves ROI.

fosters a safer work environment.

prevents over-investment in forklifts

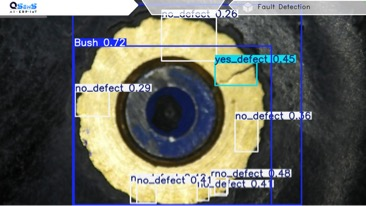

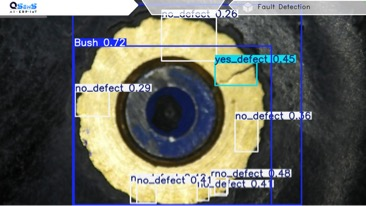

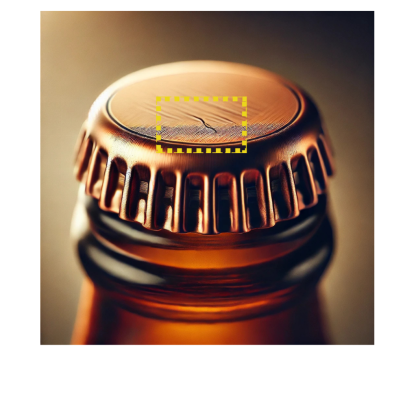

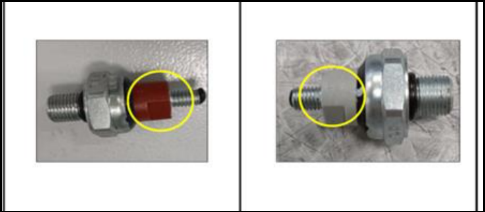

Manufacturing defects on some products are inevitable and could lead to inconsistent quality and losses.

Detects manufacturing defects instantly during production, reducing reliance on manual inspection and improving accuracy.

Helps prevent defective products from reaching customers by intercepting errors early in the assembly line.

Supports Continuous Integration and Delivery, enabling the system to evolve by seamlessly incorporating new defect scenarios as they emerge.

Automates the inspection process to minimize subjective judgment and fatigue-related oversight by human operators.

Live Testing results on actual manufacturing defects: 100% accurate fault detection conducted.

We tested these on three Zoom levels. On all three zoom levels, accuracy was 100% for parts with and without faults.

We saw 100% accuracy on 12+ orientations on each part.

100% Real-time accuracy was achieved.

Individual forklift performance tracking.

Automate and detect suspicious activity in real-time without human intervention.

Experience sustainable growth through innovative financial solutions, expert guidance, and personalized support tailored to you.

Empowering businesses with innovative, reliable, affordable solutions through cutting-edge technology and exceptional customer service.

Terms & Conditions

Privacy Policy

WhatsApp us